Since now 4 years I had at least one 3D printer in my house and I made several upgrades to them. Parts are available if you want to try and create your own version.

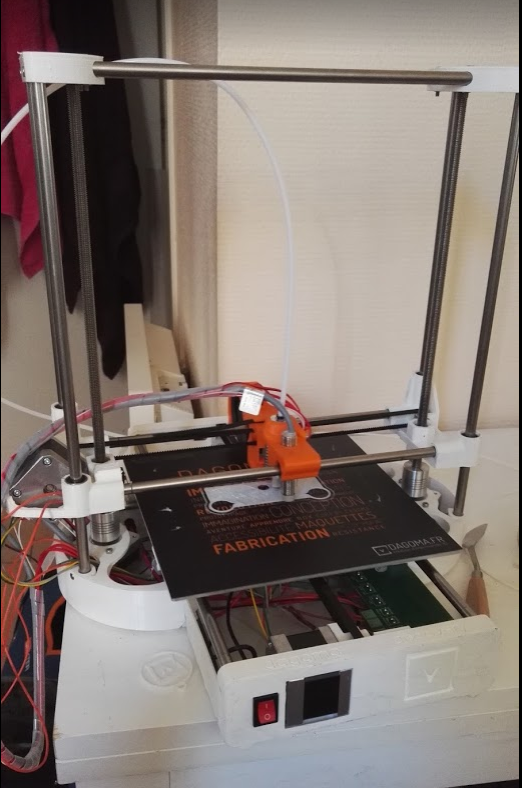

It all started with a Dagoma discovery 200 :

It has a single nozzle, no heated bed and can do a print of a size up to 20x20x20 cm3. It is an average low-quality and cheap 3D printer but it works fine.

As always, I had to try to increase the capability of my printer.

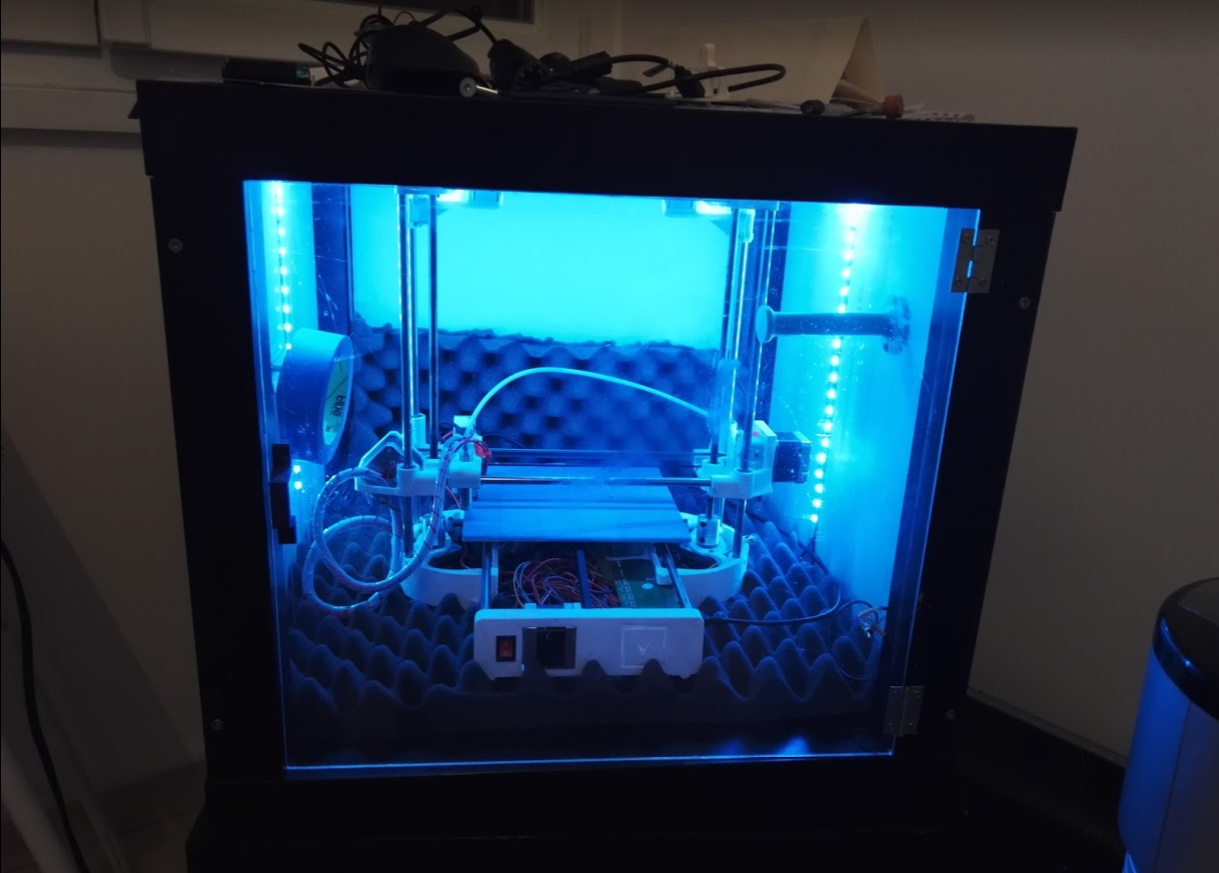

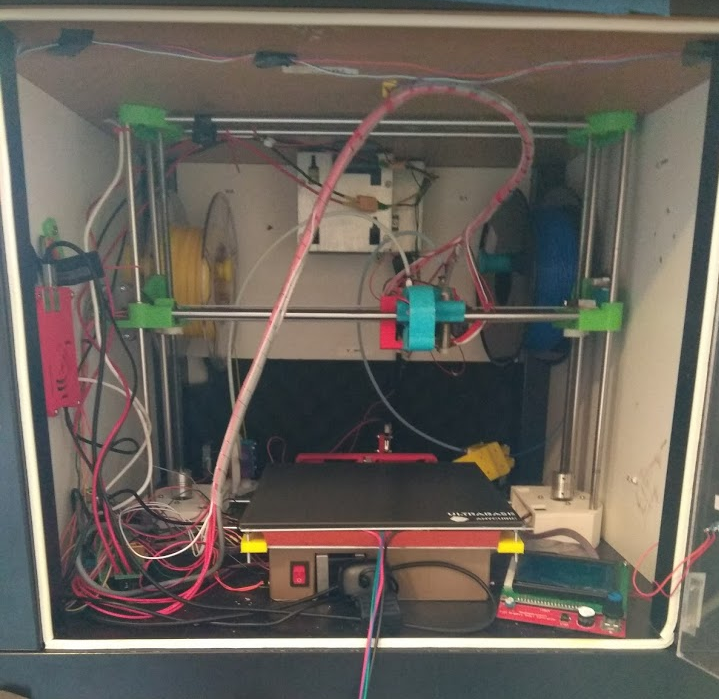

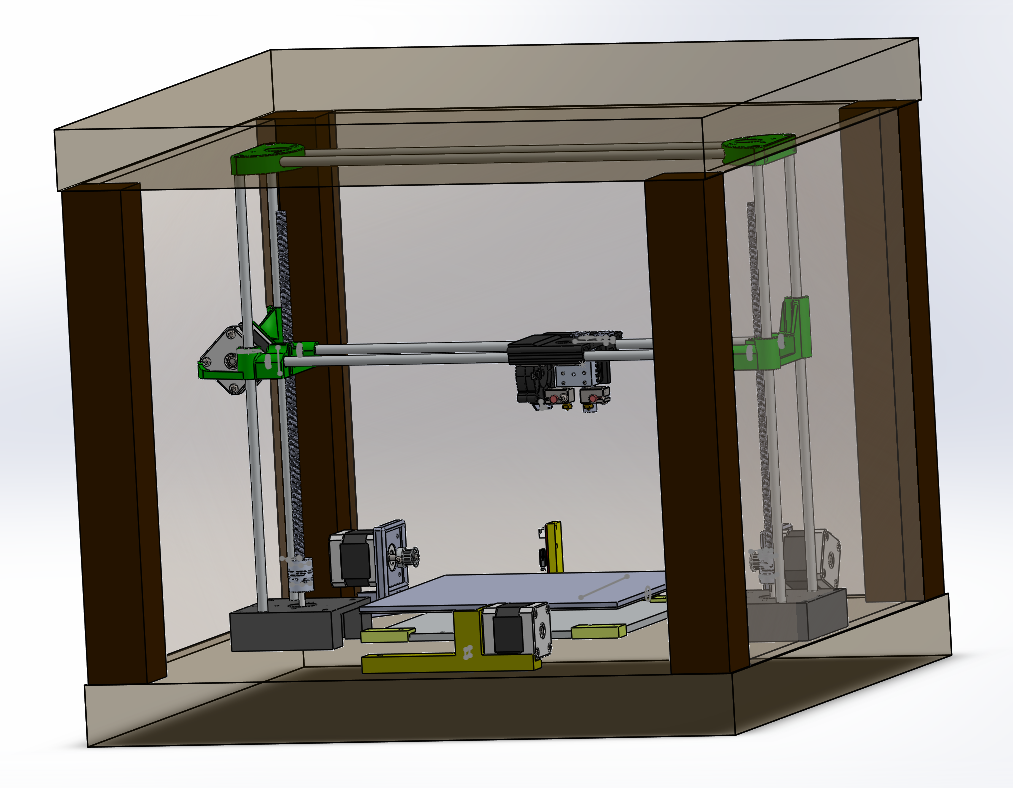

I started by building an enclosure. By using two IKEA tables I built a box to reduce noise and to light the printer when it is in use.

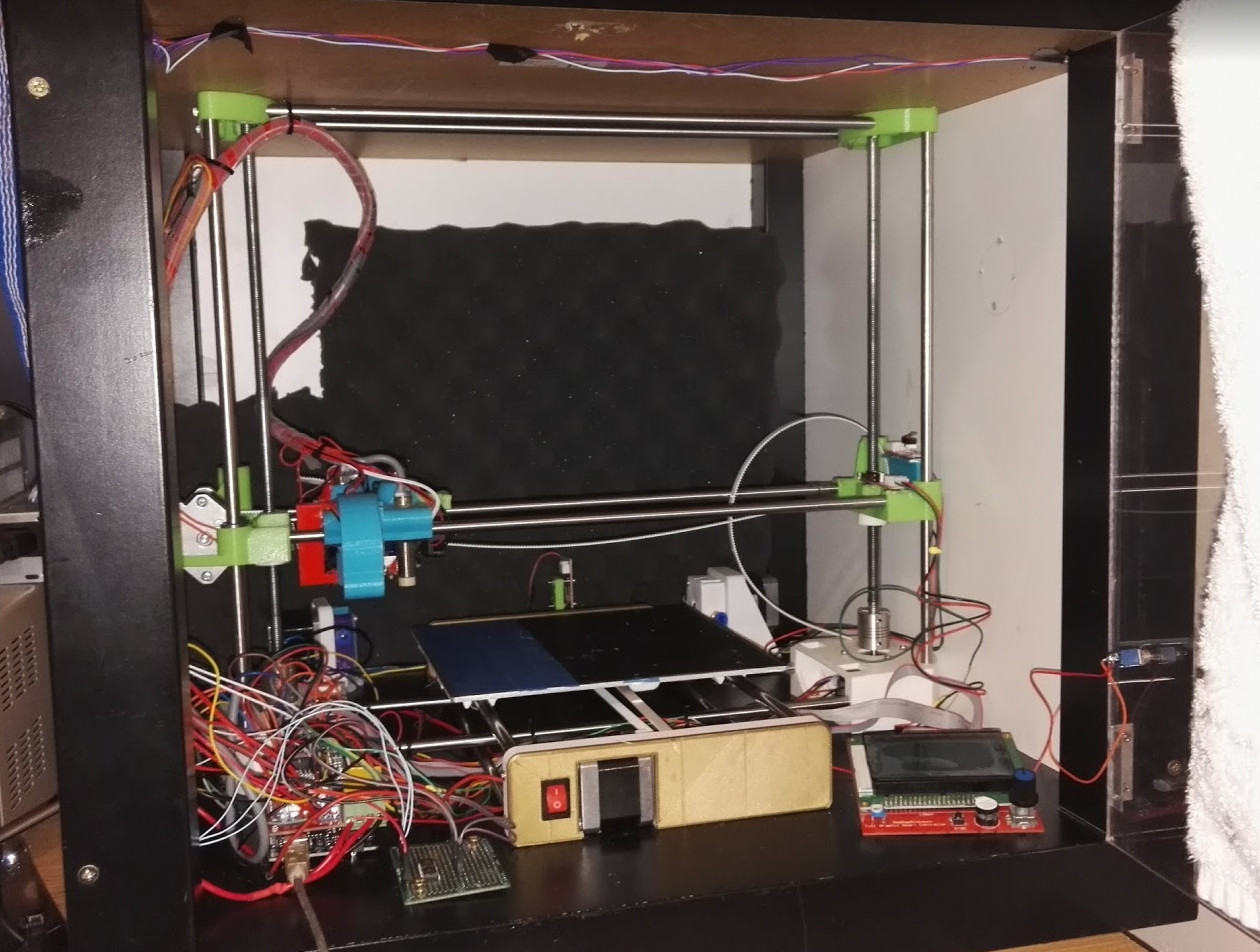

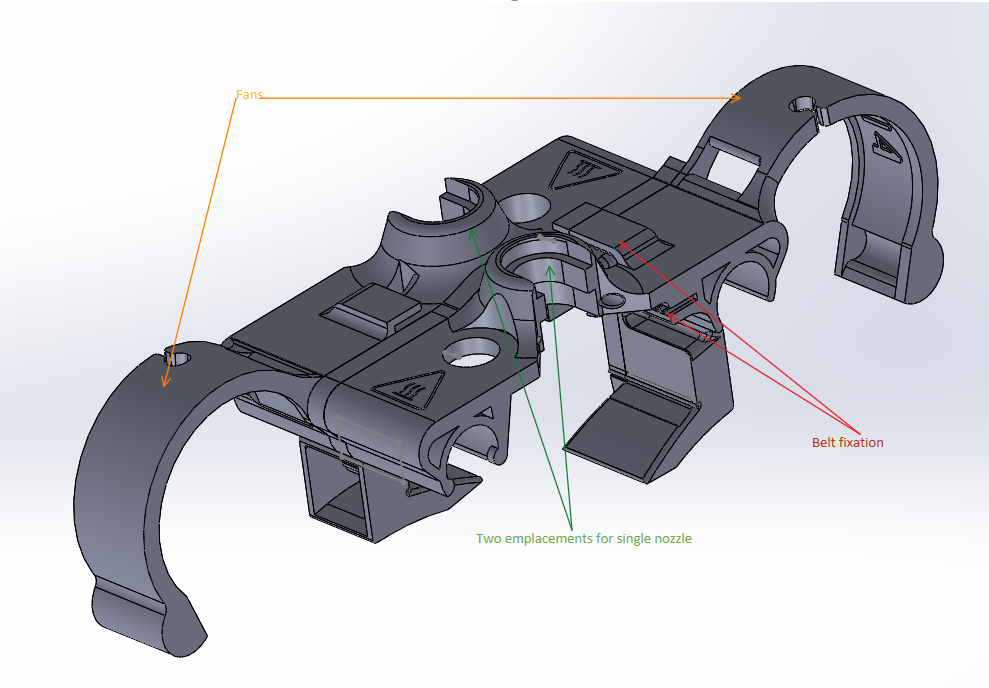

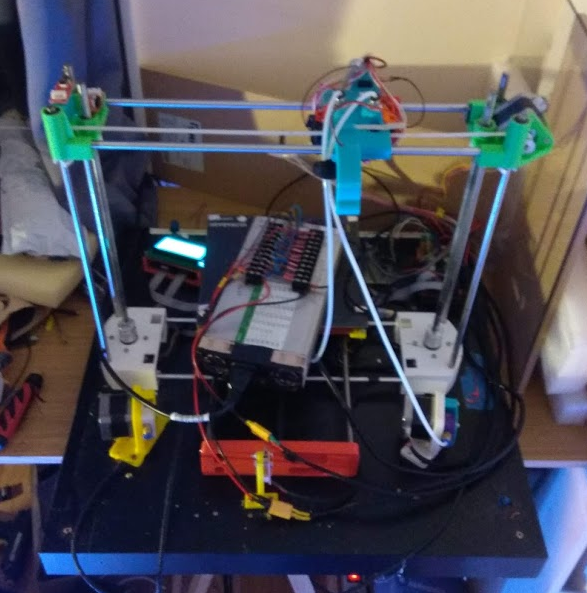

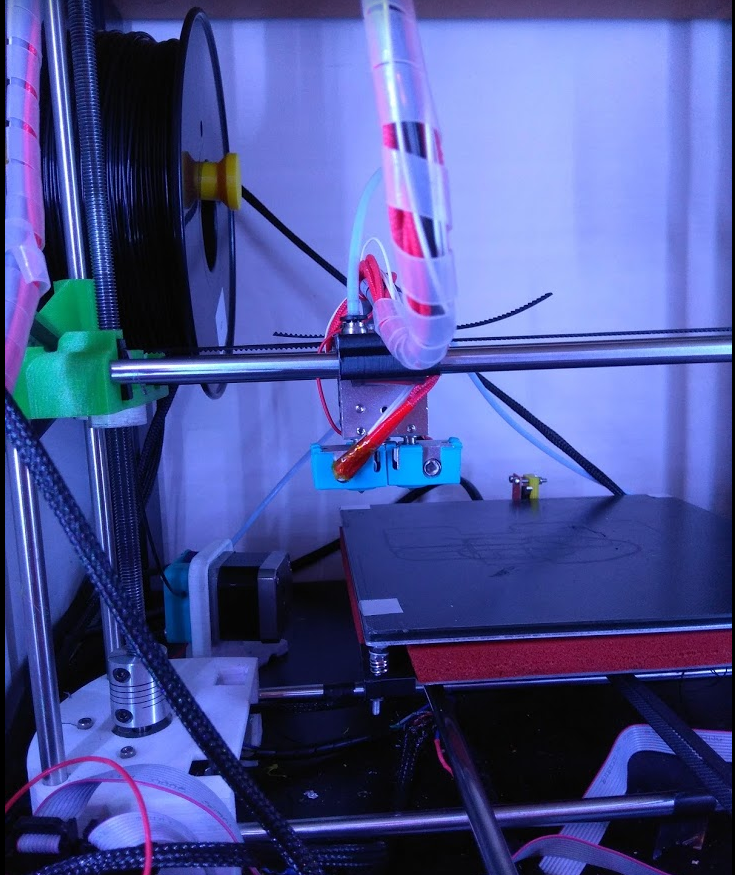

I then moved to a completely fixed and integrated frame with a new motherboard/controller board and a completely homemade dual single-nozzles.

As a prototype it turns out quite good but not enough to have reliable dual colour print.

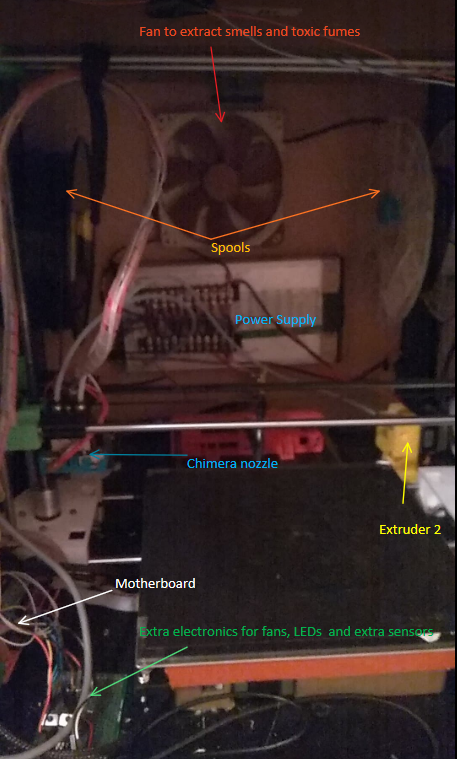

It was a big bunch of wires with the new motherboard based on an Arduino Mega (bottom left of the picture) and a RAMPS shield. I also added few MOSFET and logic electronics to control extra fans and LED strip (prototype board next to the power button).

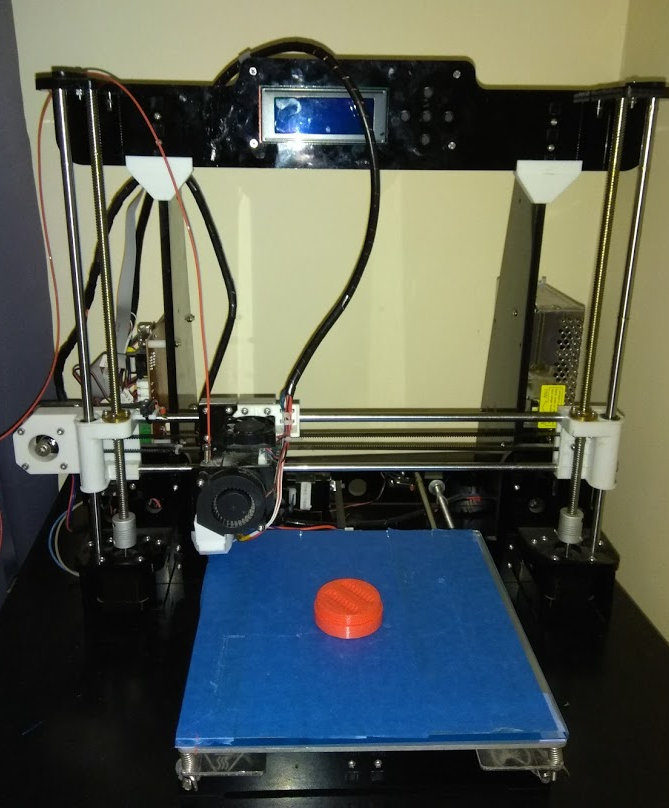

From there I got an offer to get an ANET-A8 printer for a hundred bucks. I got it for few months to play with, upgrade and print spare parts when the first one is down for maintenance. It was another good cheap and Chinese 3D printer. Probably better than my modified dagoma as it has a heated bed and a solid frame on its own. But I sold it few months after buying it as it was too similar to my other one and therefore not super fun.

One of my friends needed some solid parts for one of his project, we then decided to go for Polycarbonate plastics instead of the usual PLA/ABS.

The main difference is that Poly-carbonate need really high temperature (300°C for the nozzle and 130°C for the bed). Therefore, I bought and installed a heated bed on my printer and a Raspberry Pi to remote control the 3D printer. Thanks to the raspberry pi I didn’t have to open the door of the case and then avoiding cooling down the 3D printer which had to run at a constant temperature for 13 hours.

After that, every 3D printed parts of the frame were melted and the capacitors of the power supply became seriously bad due to the long run inside the high temperature case. So, I decided to order a new dual nozzle and found another power supply.

Dual colour became more reliable and i got the crazy offer of this FLSUN delta 3D printer from a friend for 50 bucks with some linear rails. And it makes some sick moves.

V5 of the modified Dagoma 3D printer

The cartesian 3D printer is now fully enclosed in the box which make it semi-portable and fully autonomous. No external spool holder or power supply is needed.

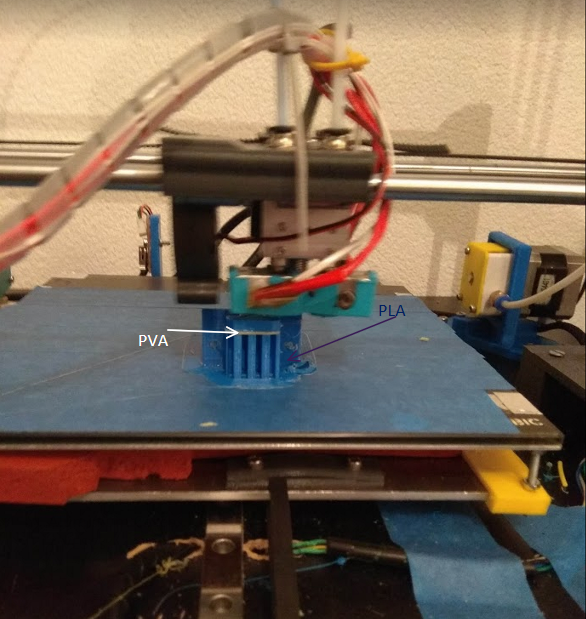

Dual colour is now quite reliable, I often use a combination of PVA(Water soluble plastic) and PLA plastics to get some removable support. A great video of it can be find at : https://youtu.be/0ENgGkPP94w?t=72

This is the final version for that printer, few things must be improved (fixation of the heated bed, rigidity, mechanical transmission …) but will be done in the next complete revision(Incoming soon).

Firmware :

Original : https://github.com/MarlinFirmware/Marlin

impressionnant ! Megan va certainement solliciter tes services 🤗

Merci , la prochaine évolution est pour très bientôt 😋.

Et tu peux fabriquer des choses amusantes avec ou le seul amusement c’est de perfectionner ton imprimante ?

Tu peux programmer un masque de carnaval par exemple ?

Bien entendu je peux, bien que je l’avoue je passe plus de temps a la perfectionner qu’à l’utiliser pour une vrai raison.

C’est tout a fait possible pour le masque !